ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

In the early morning of April 18th, an explosion occurred at the Ningxia Baofeng Energy Group Co., Ltd., resulting in the death of 2 people and the burning injuries of 4 others. Currently, the injured personnel are being treated with all efforts. The cause of the accident is under investigation.

A few months ago, there was also a deflagration accident at this company. At 21:02 on January 31st, a deflagration accident occurred in the fine chemical plant of Ningxia Baofeng Energy Group Co., Ltd., resulting in minor injuries to two nearby inspectors at the scene.

In spring, the dry weather is prone to generating static electricity, and as the temperature rises, some hazardous chemicals become volatile or accumulate heat, which can easily lead to fire or explosion accidents. The causes of accidents are diverse:

Volatility:

As the temperature rises, hazardous chemicals with low freezing points become volatile, and self-decomposing substances tend to accumulate heat, increasing the risk of poisoning, fire, and explosion accidents.

Static Electricity:

The dry spring climate is prone to generating static electricity, which can easily lead to fire and explosion accidents.

Fatigue:

As the temperature gradually warms up, employees are prone to drowsiness and fatigue, known as "spring fatigue." Close attention should be paid to the mental state of the operators.

Abnormalities:

Spring is a period of concentrated resumption of production and work, with many abnormal operating conditions during startup and a large number of special maintenance operations, which can easily lead to safety accidents.

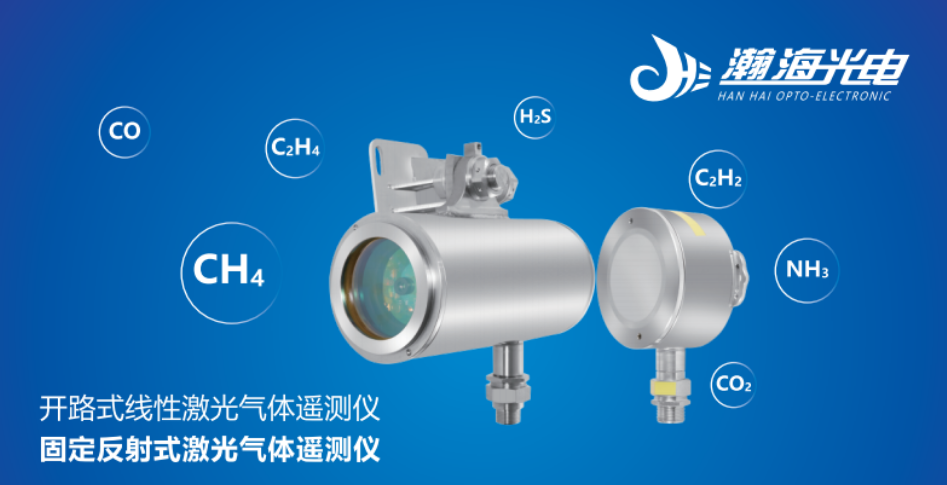

Based on the characteristics of chemical enterprises, it is recommended to replace human defense with technical prevention and adopt advanced technological means to improve detection efficiency. By installing fixed reflective laser gas telemetry meters and fixed scanning laser gas telemetry meters at the boundaries of equipment, tank areas, compressors, etc., effective detection of the leakage and spillage of hazardous gases can be achieved. Due to their wide detection range, long distance, and fast response, they provide broader detection coverage, higher safety, simpler design and construction, and cost savings compared to conventional multi-point fixed detectors.

Fixed reflective laser gas telemetry meter

The fixed reflective laser gas telemetry meter from Hanhai Optoelectronics integrates both transmitter and receiver, with a detection range of up to 1 kilometer. It has a response time of only 1 second and can accurately detect trace leaks at the ppm level, truly realizing preventive monitoring of gas leaks. Compared to traditional detectors that are susceptible to interference from environmental factors and cross-gases, it has strong anti-interference capabilities. With fingerprint-based detection, it ensures zero false alarms. The product requires no calibration, saving operational costs throughout its entire lifecycle. It can detect various gases such as methane, ethylene, acetylene, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia, and more.

Fixed scanning laser gas telemetry meter

The telemetry meter integrates laser control, spectrum acquisition, and spectrum analysis. It emits a laser beam towards the distant object being monitored, which is then reflected back to the telemetry meter. The telemetry meter analyzes the returned signal to obtain gas concentration data. By rotating in both horizontal and vertical directions, the telemetry meter scans and creates a 360° three-dimensional area similar to a radar, enabling coverage and monitoring of a large space with a detection radius of up to 300 meters. Combining detection data with video images allows managers to "see" the current detection situation, including the location being detected and gas concentration information. Leaks can be discovered and located through scanning. Multiple scanning modes can be set, with the scanning detection path freely customizable. It operates fully automatically, without the need for manual operation. It provides real-time online monitoring of gases such as methane, ethylene, acetylene, and ammonia.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone