ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

At 8:00 am on July 18th, a flash explosion occurred in the processing workshop of Guangxi Taihang New Material Co., Ltd. in Jiangzhou District, Chongzuo City, Guangxi. Thick smoke billowed from the scene, accompanied by a raging fire. Preliminary verification revealed that one person was killed and two others sustained minor injuries. The injured have been rushed to hospital for treatment. Following the incident, relevant departments such as firefighting, police, and emergency response rushed to the scene for rescue and disposal. Currently, the cause of the accident is under investigation.

A flash explosion typically refers to the sudden ignition and explosion of flammable and explosive gases (usually volatile flammable liquids) that have accumulated to a certain concentration in a relatively enclosed space with poor air circulation. Once exposed to an open flame or electrical spark, the gases will instantly ignite, causing an explosion reaction and an instantaneous expansion of their volume to a much larger proportion.

For accidents caused by flammable and explosive gases, technological prevention measures can be adopted instead of relying solely on human intervention. Online real-time monitoring equipment can be used to supervise key risk areas in the production process, thereby preventing accidents. Fixed reflective laser gas telemetry systems and fixed scanning laser gas telemetry systems can be installed at the boundaries of equipment, tank areas, compressors, etc., to effectively detect leaks and spills of hazardous gases. These systems offer advantages such as a wider detection range, longer distance, faster response time, broader detection coverage, enhanced safety, simpler design and construction, and cost savings compared to conventional multi-point fixed detectors.

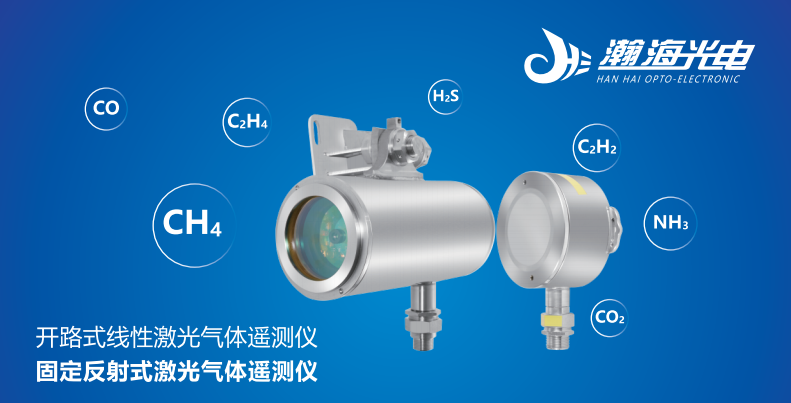

Fixed Reflective Laser Gas Telemetry System

Hanhai Optoelectronics' fixed reflective laser gas telemetry system integrates both transmitter and receiver functions, offering a detection range of up to 1 kilometer. With a response time of just 1 second, it can accurately detect trace leaks at the ppm level, truly enabling preventive monitoring of gas leaks. Compared to traditional detectors, which are prone to interference from environmental factors and cross-gases, this system boasts strong anti-interference capabilities. Utilizing fingerprint-based detection, it ensures zero false alarms. The product requires no calibration, saving operational costs throughout its entire lifecycle. It can detect a wide range of gases, including methane, ethylene, acetylene, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia, and more.

Fixed Scanning Laser Gas Telemetry System

The telemetry system integrates laser control, spectral acquisition, and spectral analysis. It emits a laser beam towards a distant object under surveillance, which reflects back to the telemetry system. The system then analyzes the returned signal to obtain gas concentration data. By rotating horizontally and vertically, the telemetry system scans and creates a 360° three-dimensional area of measurement similar to a radar, enabling coverage and monitoring of a large space with a detection radius of up to 300 meters. Combining detection data with video images allows management personnel to "see" the current detection situation, including the location being monitored and gas concentration information. Scanning can detect leaks and locate the leak points. Multiple scanning modes can be set, allowing for flexible configuration of scanning paths. Fully automated operation eliminates the need for manual intervention. Real-time online monitoring of gases such as methane, ethylene, acetylene, and ammonia is possible.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone