ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

On the evening of May 22nd, it was reported that a sudden fire broke out near Doumen, Zhuhai, Guangdong Province, with fierce flames and accompanying explosions. The Zhuhai Fire and Rescue Detachment announced that it was a silicon products company, and there were no casualties so far.

During the hot summer months, it is also the peak production season for factories and enterprises. Factories consume large amounts of electricity, have densely populated workshops, and warehouses filled with flammable and combustible materials, making them prone to accidents if caution is not exercised.

These types of enterprises must pay particular attention:

Pharmaceutical Enterprises

Pharmaceutical production and manufacturing enterprises often deal with flammable, toxic, and hazardous materials. In the event of a leak, the impact on the surrounding environment can be significant.

Petrochemical Enterprises

Petrochemical enterprises are characterized by complex and variable production processes, large-scale production facilities, continuous operational processes, and the use of flammable, explosive, toxic, hazardous, and corrosive raw materials and products. These factors make them highly dangerous.

Hazardous Chemical Storage Enterprises

Storage warehouses are areas where materials are highly concentrated, leading to a significant fire load. Coupled with the presence of flammable, explosive, toxic, and hazardous gases, complex internal layouts, insufficient fire-fighting equipment, and lack of fire water sources, the economic losses in the event of a fire can be severe.

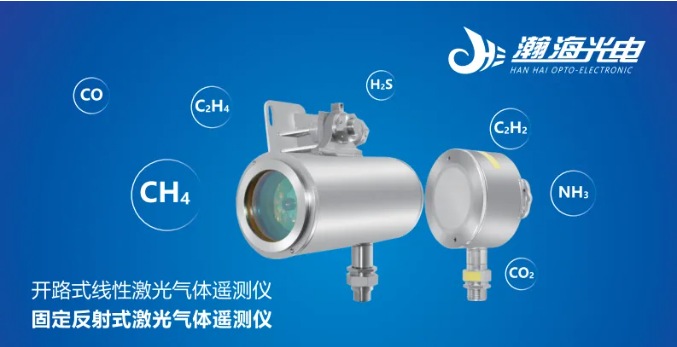

The causes of accidents are diverse, but special attention must be paid to those involving hazardous gases. Accidents caused by hazardous gas leaks can be addressed by adopting technical prevention measures instead of relying solely on human prevention. By using online real-time monitoring equipment to oversee key risk areas in factories, accidents can be prevented. Installing fixed reflective laser gas telemetry meters and fixed scanning laser gas telemetry meters at the boundaries of equipment, tank areas, compressors, and other locations can effectively detect leaks and spills of hazardous gases. Due to their wide detection range, long detection distance, and fast response time, these instruments offer broader coverage, increased safety, simpler design and installation, and cost savings compared to conventional multi-point fixed detectors.

Fixed Reflective Laser Gas Telemetry Meter

The fixed reflective laser gas telemetry meter from Hanhai Optoelectronics integrates both transmitter and receiver, achieving a detection distance of up to 1 kilometer. With a response time of just 1 second, it can accurately detect trace leaks at the ppm level, enabling truly preventive monitoring of gas leaks. Compared to traditional detectors, which are prone to interference from environmental factors and cross-gases, this device boasts strong anti-interference capabilities. Its fingerprint-based detection ensures zero false alarms. The product requires no calibration, saving operational costs throughout its entire lifecycle. It can detect a wide range of gases including methane, ethylene, acetylene, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia, and more.

Fixed Scanning Laser Gas Telemetry Meter

The telemetry meter integrates laser control, spectral acquisition, and spectral analysis. It emits a laser beam towards a distant object under surveillance, which reflects back to the telemetry meter. The telemetry meter then analyzes the returned signal to obtain gas concentration data. By rotating horizontally and vertically, the telemetry meter scans to create a 360° three-dimensional monitored area similar to a radar, enabling coverage and monitoring of a large space with a detection radius of up to 300 meters. Combining detection data with video images allows management personnel to "see" the current detection status, including the location being monitored and gas concentration information. Leaks can be detected and localized through scanning. Multiple scanning modes can be set, allowing free configuration of scanning and detection paths. Operating fully automatically, it requires no manual intervention. It provides real-time online monitoring of gases such as methane, ethylene, acetylene, and ammonia.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone