ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

July 14, Anhui emergency management department released“Anhui Maanshan Venus Titanium White (Group) Co. , Ltd. , “3.10” large poisoning and asphyxiation accident investigation report.

The direct cause of the accident

The operators of Venus Titanium White Company violated the regulations on the safety management of operations in restricted space, to enter the No. 1 mud bucket without effective safety isolation measures, effective ventilation, gas detection and wearing of personal protective equipment as required by the standard, because of the inhalation of hydrogen sulfide and other toxic gases lead to the accident; rescue personnel in the case of not doing a good job of individual protection blind rescue, resulting in increased casualties.

Source analysis of hydrogen sulfide

1. In the process of acidolysis of titanium concentrate, some sulfides in the ore produce hydrogen sulfide under the action of sulfuric acid, a small amount of unreacted sulfides and hydrogen sulfide dissolved in the titanium solution enter the mud bucket with the mud.

2. In the mud bucket, the mud is stirred and heated by steam, and a small amount of unreacted sulphides continues to react with the dilute sulfuric acid in the mud to produce hydrogen sulfide and hydrogen sulfide dissolved in the titanium liquid escapes.

3. At the time of the accident, No. 2 and No. 3 mud buckets were in normal production, which were connected with the tail gas pipeline of No. 1 mud barrel, and no induced draft fan was installed on the pipeline. No. 1 mud barrel maintenance, from No. 2, No. 3 mud barrel contains hydrogen sulfide and other toxic waste gas into the No. 1 mud barrel caused accumulation.

Hydrogen sulfide has a colorless, strong rotten egg odor characteristics. It is heavier than air and tends to accumulate in low-lying areas.

So how can we prevent hydrogen sulfide poisoning in the end in safe production?

In addition to identifying key protection areas and key protection operations for hydrogen sulphide, fixed hydrogen sulphide detection alarms should be installed in workplaces where hydrogen sulphide leakage may occur, indicating that the alarm panel should be located in the control room, the number and position of hydrogen sulfide detection probe on site shall be arranged in accordance with relevant specifications.

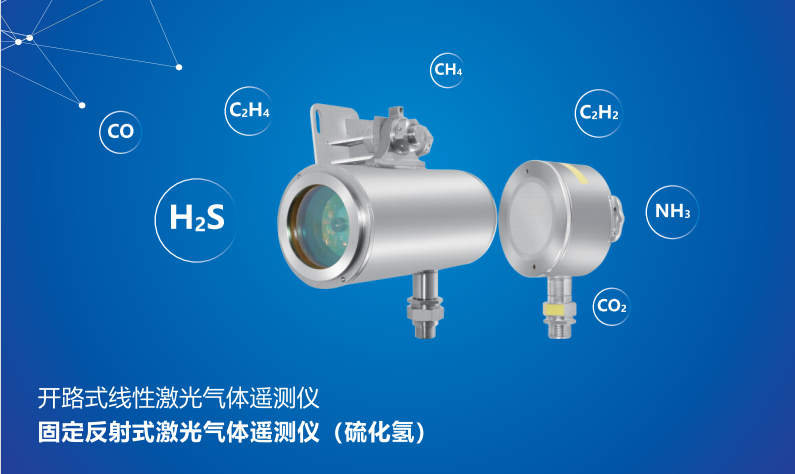

01 The fixed reflection laser gas telemeter of Hanhai photoelectricity is integrated with the transmitter and receiver, and the detection distance of hydrogen sulfide can reach 100 meters.

02 Different from the traditional passive waiting mode, it can monitor the leakage risk actively.

03 Response time is only 1 second, can accurately detect ppm micro-leakage. To realize the preventive monitoring of gas leakage.

04 Compared with the traditional detector, it is easy to be interfered by environment and cross gas. Fingerprint detection, truly achieve zero false positives.

05 The product need not adjust, but can save the operation cost in the whole life cycle.

06 In addition to hydrogen sulfide, but also detect methane, ethylene, acetylene, carbon monoxide, carbon dioxide, ammonia and other gases. Comply with national GB/T 50493-2019 standard.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone