ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

Recently, the Fujian Provincial Department of Residence and construction issued the implementation measures for the safety inspection of the use of fuel gas in catering places in Fujian province (trial implementation)(hereinafter referred to as“The implementation measures”) , in order to further strengthen the safety management of fuel gas in catering places, we will establish a sound long-term mechanism for gas safety inspection and listing management in food and beverage establishments. The implementation measures clearly state that the objects of administration shall be restaurants, restaurants and canteens (including canteens of organs, enterprises and institutions) using gas in the whole province, provide catering services in hotels, bathing places, dance halls and other places of entertainment. Where fuel gas is used, a fuel gas safety public sign shall be hung, and the information of the public sign and the safety inspection shall be filled in by the users of the food and beverage and the inspectors of the fuel gas business enterprises respectively, “Implementation measures” has also clearly defined the contents of public signs and the requirements to be met. A fuel gas business enterprise shall establish and improve a safety inspection system for the use of food and beverage premises, carry out the responsibility of the main body of the enterprise, and be responsible for the daily inspection of the use safety of the food and beverage users supplied by the gas business, the public announcement of the listing, the rectification and implementation of hidden dangers, etc. . The fuel gas business enterprise shall carry out safety inspection once a month for restaurant users who use pipeline fuel gas, and shall increase the frequency of inspection for important regions and large users, safety inspection must be carried out before opening new accounts and resuming gas supply after shutdown. The contents of the safety inspection for catering users include the environment of the premises, equipment and facilities, as well as the implementation of the rules and regulations, etc. , record the safety status, existing problems, rectification requirements and so on, implement the responsibility system of inspection and rectification, form a closed-loop management.

The traditional combustible gas detector needs regular adjustment, and has the false alarm to miss the report, after using for a long time will produce the drift phenomenon, can not guarantee the normal operation at all times. For the restaurant, is not a regular adjustment of the conditions. Therefore, to promote the installation of a non-tuning, stable flammable gas detector is to ensure the safety of gas catering the best program.

Passive fiber laser leakage monitoring system

The passive fiber laser leakage monitoring system consists of a monitoring platform, a photosensitive terminal and an electromagnetic valve. The monitoring platform is placed in the monitoring center, the photosensitive terminal is placed in the gas-using fire scene, and the solenoid valve is placed at the gas pipeline entrance. The platform is connected with the photosensitive terminal and the solenoid valve by optical fiber to form a gas safety monitoring network. Once the gas leak occurs, the system drives the solenoid valve to cut off the gas source immediately to prevent the explosion. When the unit air reaches the safety standard, the system automatically restores the air supply.

No power supply is required on site

The system mainframe can be installed dozens of kilometers away, and gas-fired monitoring sites only need to install passive photosensitive terminals (pure optical equipment, no power supply) . The real-time and on-line monitoring of combustible gas is realized by remote monitoring platform in the area where restaurants gather.

No calibration is required

The passive optical fiber laser leakage monitoring system does not need regular calibration and maintenance to ensure its normal use. No error report can improve the reliability of gas detection.

Long Life

Using semiconductor light source, optical glass, no contact measurement, no physical loss, life up to 10 years. Therefore, the lifetime of passive fiber laser leakage detection equipment is 10 times that of traditional detection equipment.

More stable

The stability of traditional detection equipment is poor, and it is easy to be impacted and poisoned by the high concentration of gas leakage. This problem does not exist in passive fiber laser leak monitoring equipment. More stable performance.

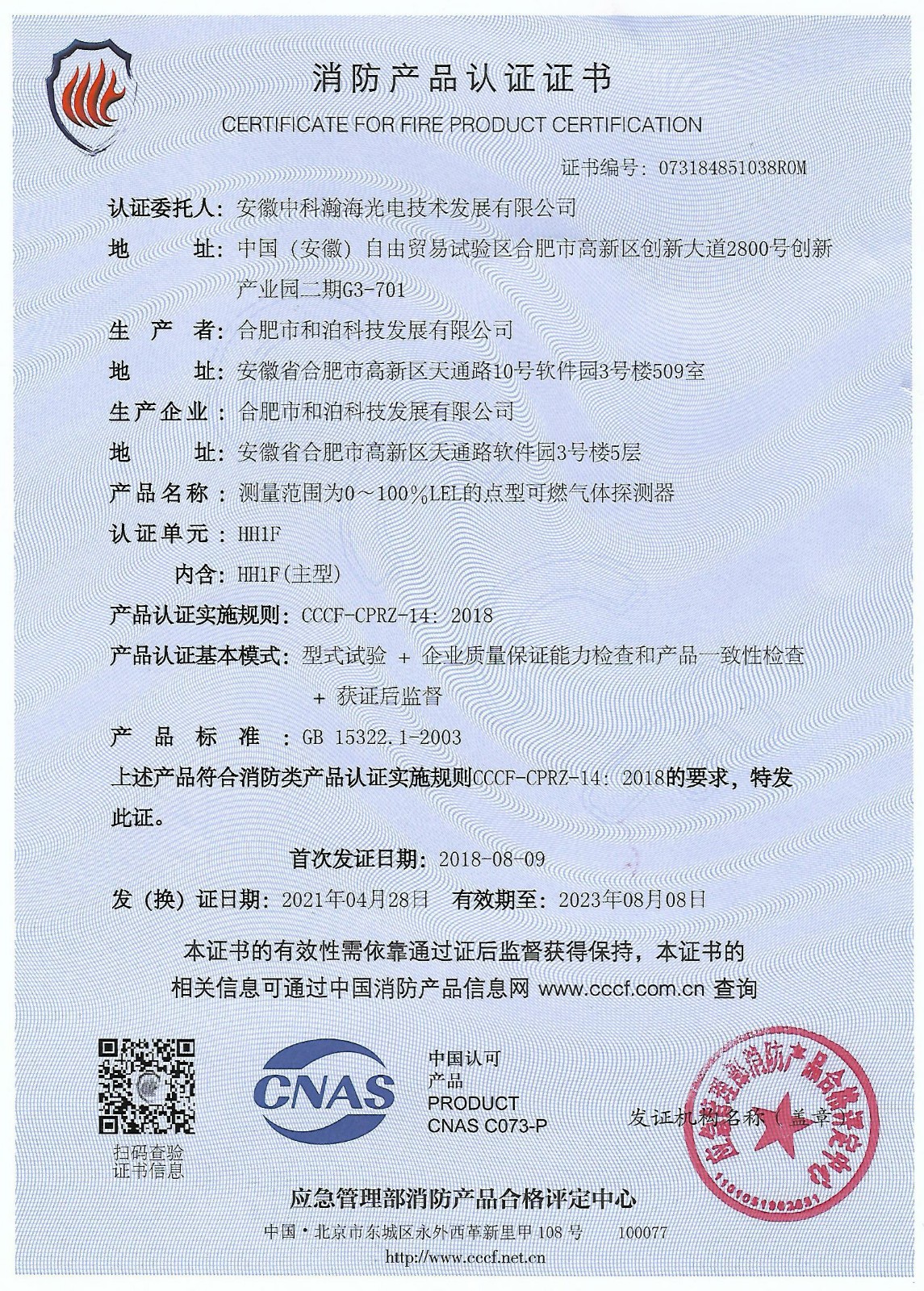

Unique fire protection certification in laser industry

Laser on-line monitoring system for active internet of things

On-site visualization of gas monitoring concentration

With the display screen, the scene can be real-time display gas monitoring concentration, timely to avoid the occurrence of potential accidents.

Sound and light on-site alarm more intuitive

With on-site sound and light alarm function, fault prompt function. Gas leak the first time to remind the user, do a good job in a timely manner on-site staff evacuation.

More diverse means of communication

Can choose wired communications (RS485 or 4-20ma) , wireless communications (NB-Iot or 4G) , GPS or bluetooth communications, adapt to a variety of communication scenarios.

High protective performance

IP68 protection of the highest level, explosion-proof level up to Exd I a IIC T 6GB.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone