ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

At 4:28 on June 18, a fire broke out in the ethylene glycol unit area of Sinopec Shanghai Petrochemical Department.

According to the news on Shanghai Petrochemical online at about 10:30 today, after preliminary verification, the accident has caused a slight scratch on the arm of an employee of Shanghai Petrochemical and the death of a third-party transport vehicle driver. The specific cause is under further investigation.

Just two days ago, an explosion occurred in Qinchuan fine chemical industry park in Lanzhou New Area. At 18:58 on June 16, an explosion occurred in the sludge drying workshop of Gansu binnong Technology Co., Ltd. located in Qinchuan fine chemical industry park, Lanzhou New Area, resulting in 8 injuries and 6 loss of contact.

June this year is the 21st national "safety production month", and June 16 is the national safety publicity and consultation day. But the recent chemical industry enterprise accident is unceasing, which is really distressing.

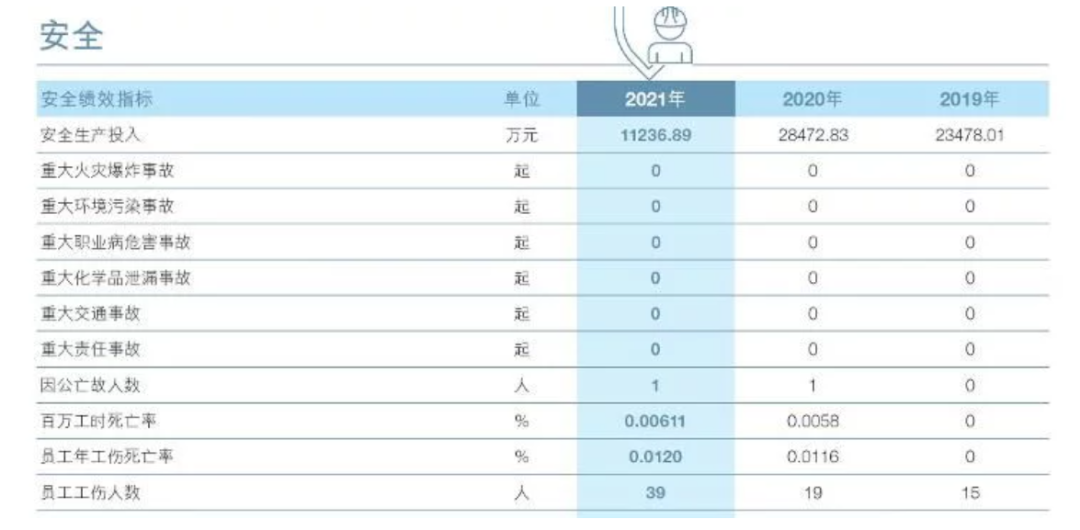

According to the social responsibility report disclosed by Shanghai Petrochemical, from 2019 to 2021, the company's safety production investment was RMB 235million, RMB 285million and RMB 112million respectively, with a year-on-year decrease of 60.53% in 2021. In the last three years, the number of employees with work-related injuries was 15, 19 and 39 respectively.

According to the annual report data of the past two years, from 2019 to 2021, the repair and maintenance expenses of Sinopec Shanghai were 1.09 billion yuan, 1.06 billion yuan and 380million yuan respectively.

The ethylene glycol production capacity of Sinopec Shanghai Petrochemical Co., Ltd. is 1 × 225000 tons and 2 × 38000 tons. Previously, 1 × plant mainly produced epoxy, and the operating load of 2 × plant was around 30%. The 380000 ton units shut down account for about 1.73% of the total capacity of the domestic ethylene glycol industry.

Safety management equals economic benefit

Numerous accidents have proved that if an enterprise does not pull out a dime of safety, the accident will help you pull out a dime!

Case 1: a 10 times Bull Stock Factory exploded, 2 people were seriously injured, and the stock price fell by the limit! 1.8 billion market value evaporation

On the evening of July 27, 2020, an explosion accident occurred in a factory under Zhejiang sitaili, resulting in the failure of normal production in the iohexol crude product production workshop. On the evening of the 28th, steli further announced that the explosion had killed 2 people and injured 4. The workshop and production equipment were seriously damaged and had been shut down for self-examination. After the accident, steli's stock fell by the limit, and its market value evaporated by 1.8 billion.

Case 2: fire caused by accidental explosion in the plant, and the share price of Zhuoyue Xinneng plummeted

On July 13, 2020, the opening price of Zhuoyue new energy fell by 14%. At 10:00 a.m. on July 12, a fire accident occurred in Dongbao plant of Longyan Zhuoyue new energy Co., Ltd. during equipment maintenance.

Case 3: the explosion accident of Fangda special steel caused 6 deaths and 4 injuries, and the share price plummeted by 9% at the opening

On June 19, 2019, "5.29" explosion accident of Fangda special steel has caused 6 deaths. On May 29, the gas pipeline of No. 2 blast furnace in the ironmaking branch of Fangda special steel company exploded, and the coke ejected from the furnace fell, killing one person and injuring nine others. On June 19, the death toll rose to six.

Safety code for special operations in hazardous chemical enterprises

The revised national standard safety code for special operations in hazardous chemical enterprises (GB 30871-2022) organized by the emergency management department has been officially released and will be implemented on October 1, 2022. In the revised new standard, it is mentioned for many times that enterprises that produce, operate (store) hazardous chemicals and chemical and pharmaceutical enterprises need to be equipped with mobile gas detection and alarm devices to monitor the concentration of combustible gas, toxic gas and oxygen during operation.

A series of accidents tell us the importance of safety management in hazardous chemical enterprises! The importance of hidden danger troubleshooting! Importance of safety hazard early warning equipment input! At the same time, hazardous chemical enterprises also have the challenge of detecting diverse gases and complex environment. So how can we accurately and quickly identify hidden dangers of gas leakage?

The traditional gas detectors are unstable, easy to be disturbed, and have high false alarm rate. In this regard, Hanhai technology group, in cooperation with the Chinese Academy of Sciences, undertook the industrialization of laser absorption spectrum gas detection technology, a major national scientific research achievement. The equipment can realize on-line, high accuracy, calibration free, highly sensitive and reliable detection under the environment of strong acid, strong alkali and various gas interference.

Fixed reflection laser gas telemeter

Hanhai photoelectric fixed reflection laser gas telemetry instrument is composed of laser control unit, spectral analysis unit and optical reflection unit. It adopts laser absorption spectral gas detection technology (TDLAS) to conduct long-distance all-weather online monitoring of gas concentration between laser transceiver and reflection device. Through the networking of multiple devices, the real-time monitoring of the distribution concentration, moving speed and moving direction of different component gases can be realized. It is an ideal choice for monitoring gas leakage in a large open area. It is very suitable for the scenario application of hazardous chemical production enterprises, hazardous chemical storage enterprises and chemical industry parks.

01. Wide detection area

The fixed reflection laser gas telemeter can detect methane at a distance of 1km, and can detect ethylene, acetylene, hydrogen sulfide and other gases at a distance of 200m.

02. Preventive monitoring

Different from the passive waiting of traditional detection mode, it actively monitors the leakage risk points. The response time is only 1 second, which can accurately detect ppm level micro leakage. Truly realize the preventive monitoring of gas leakage.

03. Convenient installation

The laser transmitting end and receiving end are integrated at one end, and the other end is only equipped with a reflecting device, which is convenient to install.

04. Strong anti-interference ability

Compared with traditional detectors, which are easily disturbed by environment, cross gas and other factors, the anti-interference ability is strong. Fingerprint detection, truly achieve zero false alarm.

05. Accurate measurement

The leakage gas concentration is quickly obtained by spectral inversion algorithm, and the sensitivity is up to 1ppm m. Completely eliminate the phenomenon of false positive and false negative.

06. "0" maintenance

The product does not need to be adjusted, which can save operation in the whole life cyclcost.

07. Long service life

The service life of the product is up to 20 years.

08. Detection of gas diversification

Gas detection type: methane, carbon monoxide, hydrogen sulfide, and ethylene

Alkene, acetylene and ammonia (more gas detection schemes can be provided according to customer needs)

Fixed scanning laser gas telemeter

The fixed scanning laser gas telemetry instrument can monitor the gas concentration with 360 ° rotation scanning of radar within a radius of 300 meters, so as to monitor the gas concentration data in real time and conduct remote online visual intelligent monitoring in combination with high-definition video. Leak orientation can be located. It is applicable to the operation occasions requiring large-scale monitoring.

01. Visual intelligent monitoring

Combined with high-definition video, the on-site concentration data can be monitored remotely 24 hours a day. It can detect trace gas leakage in an all-round way and accurately judge the leakage direction.

02. Wide detection area

The fixed scanning laser gas telemeter can carry out 360 degree rotation scanning on the area with a radius of 300 meters, and can monitor the leakage in the target area of 280000m2 at most. Suitable for large-scale operation.

03. Preventive monitoring

Different from the passive waiting of traditional detection mode, it actively monitors the leakage risk points. The response time is only 0.1 seconds, which can accurately detect ppm level micro leakage. Truly realize the preventive monitoring of gas leakage.

04. Night vision infrared system

Night vision infrared system, 2million pixels, 25X optical zoom.

05. High integration

With the integrated design of detector, camera and PTZ, the equipment can operate independently. Without the control of other equipment, it can complete the scanning movement, detection and alarm functions, and communicate with the upper computer.

06. Monitoring of key areas can be set

Key areas can be monitored at key flange joints and valves, and different scanning modes can be set to realize no dead angle monitoring of important areas and key points.

07. Strong anti-interference ability

Compared with traditional detectors, which are easily disturbed by environment, cross gas and other factors, the anti-interference ability is strong. Fingerprint detection, truly achieve zero false alarm.

08. "0" maintenance

The product does not need to be adjusted, which can save the operation cost in the whole life cycle.

09. Long service life

The product has good stability without regular adjustment and maintenance, and its service life is up to 20 years.

10. Multi gas detection

Capable of detecting methane and ethylene gas.

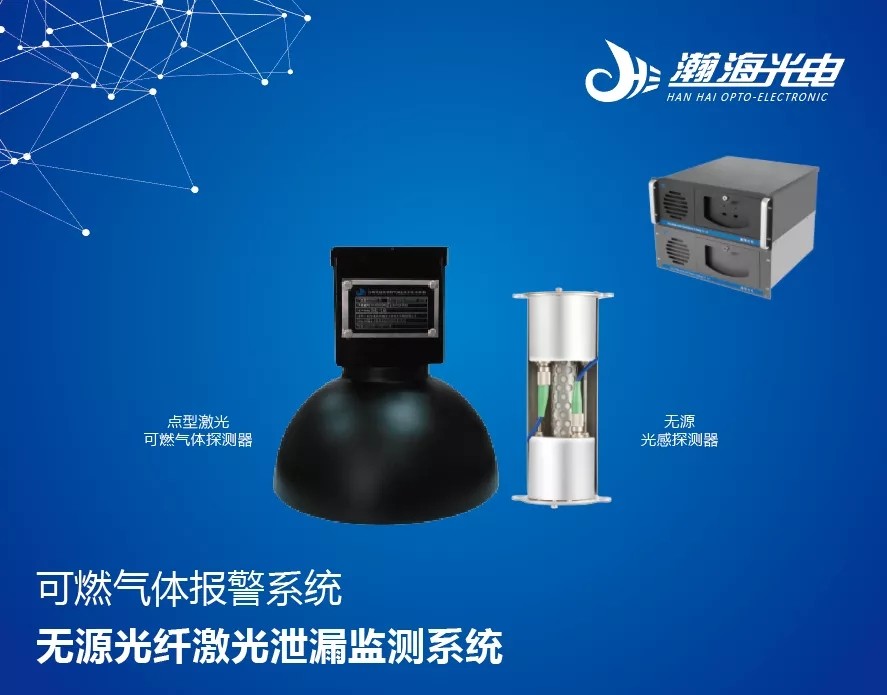

Passive fiber laser leak monitoring system

The Hanhai photoelectric passive fiber laser leakage monitoring system consists of a laser monitoring platform and a passive laser detector. The platform and the detector are connected by optical fiber to form a safety monitoring network.

01. No power required

The system host can be installed tens of kilometers away, while the monitoring site only needs to install passive optical terminals (pure optical equipment, no power supply). Through the remote monitoring platform, real-time online monitoring of combustible, toxic and harmful gases can be realized.

02. No calibration required

The passive optical fiber laser leakage monitoring system does not need regular calibration and maintenance, which can ensure its normal use. No false alarm can improve the reliability of gas detection.

03. Long service life

With semiconductor light source and optical glass, there is no physical loss in non-contact measurement, and the service life can reach decades. Therefore, the service life of passive fiber laser leakage monitoring equipment is 10 times that of traditional detection equipment.

04. More stable

The traditional detection equipment has poor stability and is vulnerable to impact and poisoning caused by excessive concentration of flammable, toxic and harmful gas leakage; Then detect the failure. Passive optical fiber laser leakage monitoring equipment does not have this problem. More stable performance.

05. Multi gas detection

Capable of detecting methane and ethylene gas.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone