ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

“We should put safety first and give priority to prevention, establish a framework for major safety and emergency response, improve the public safety system, and promote the transformation of the Public Security Governance model to pre-emptive prevention.”

General Secretary in the report of the 20th National Congress of the Communist Party of China (CPC) , an important plan was made to improve the level of public security administration, and the forward coordinates and direction of work safety in the new era were marked.

Facing the national important public security strategic demand, the petrochemical enterprise should actively explore the pre-prevention intelligent solution. This requires in-depth analysis of the petrochemical plant process media leakage risk.

The process media of petrochemical plants include all kinds of hydrocarbons from hydrogen and methane to fuel oil, organic chemicals such as alcohol ether ketone aldehyde, alkyl aluminium, peroxide, etc. , and has different degrees of toxicity, asphyxiation.

Operating equipment includes high-temperature equipment with open flame such as cracking furnace, heating furnace, heat release hydrogenation reactor, polymerization reactor, oxidation reactor, as well as large compressor, refrigeration compressor; In addition, there are high and low temperature fractionation tower, heat exchanger, cold box and larger low-temperature storage tanks, a large number of pumps, as well as a large number of pipes, fittings, valves and so on.

The main leak-prone parts are:

1, compressor, mixer and liquid pump seals, due to long-term rotation wear, easy to leak. Such as March 18,2010, a company in Guangzhou four atmospheric and vacuum distillation of the wax pump seal leak fire, causing equipment damage, multi-set device shutdown.

2. Equipment, pipes, fittings, valves flange connections due to gasket failure or stress or material corrosion caused by perforation leakage. Flanges that are especially frequently removed and frequently operated valve sets are prone to leakage. Such as many years ago, a petrochemical plant in northeast China, the bottom of the discharge line valve for the low temperature gasket failure occurred leakage, resulting in a fire.

3. The liquid sampling port and the gas sampling port.

4. Drain outlet and drain outlet containing flammable liquid.

5. Because most combustible media, including C _ 3 and heavier hydrocarbon components, are heavier than air, it is easy to accumulate combustible gas in places with poor ventilation, such as geosyncline, process valve wells, etc. , underground equipment pit, sealed cover of sewage trench, underground cable trench, etc. , are often or in the production of abnormal conditions prone to the accumulation of combustible gas.

Leakage of process media is the main cause of fire, explosion and poisoning accidents:

When the mixture of flammable gas, oil gas, dust and air reaches the explosion limit, once it is ignited, fire and explosion will take place, the radiant heat of fire and the shock wave produced by explosion can kill and destroy people, equipment and buildings. In particular, a large number of flammable gas or oil and gas leakage formed by the steam cloud explosion, often destructive.

For example, in 2001 Fushun Petrochemical Company's ethylene air separation device explosion, Jilin Baoyuan ammonia leak explosion killed more than 100 people accident, the losses are very heavy.

How can we prevent the leakage of dangerous materials in the process unit?

The flammable gas detection alarm must be arranged at the leak-prone part of the process medium. (see GB/T50493 -2019,4.1.3) when the process medium contains highly toxic gases such as hydrogen sulfide, ammonia and carbon monoxide, the highly toxic gases will diffuse with the wind once the leak occurs, dangerous materials that are especially light than air can spread farther. Will cause human injury and environmental pollution, the greater the harm. Therefore, these leak-prone parts should be equipped with toxic gas detection alarm. Of particular note is ammonia, which is classified as a mild hazard in the old code GB5044-85, but has been classified as a highly toxic substance in the“List of highly toxic substances”(WEIFA JIANFA [2003] No. 142) . Therefore, the leakage of ammonia media must be equipped with the toxic gas detection alarm. In addition, there should be a certain number of portable combustible gas and toxic gas detectors for petrochemical devices with the possibility of flammable, explosive and toxic gas leakage.

The detector shall be located within 2.0 m above the release source when detecting flammable or toxic gases lighter than air. The detector should be located 0.3-0.6 m above the floor or floor to detect the flammable gas or toxic gas heavier than air.

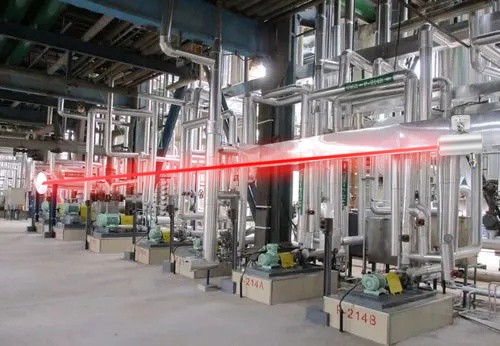

According to the standard requirements and the characteristics of petrochemical process units, a fixed reflective laser gas telemeter can be used to monitor the process units in real time.

Network monitoring

The monitoring range can be up to 1 km, and the real-time monitoring of distribution concentration, moving speed and moving direction can be realized by multi-device network.

Preventive monitoring

Active monitoring of leakage risk point, response time is only 1 second, can accurately detect ppm micro-leakage. To realize the preventive monitoring of gas leakage.

Strong anti-interference

Compared with the traditional detector, it is easy to be interfered by environment and cross gas. Fingerprint detection, truly achieve zero false positives.

Detect a variety of gases

The type of detectable gas basically covers all the gases required by the petrochemical industry, and can be compatible with the petrochemical GDS system.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone