ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

Recently, the Suzhou region launched a limited space“Locked cabinet” campaign, demanding that the limited space space to improve the safety equipment special cabinet settings, equipped with effective breathing apparatus, gas mask, communication equipment, safety ropes and other emergency equipment. Through the establishment and implementation of the“Lock-in” management system, the security hidden danger of the effective space is firmly sealed.

With the implementation of the code of safety for special operations of Hazardous Chemical Enterprises, limited space operations have also become the focus of reform, the bottom line is raised again, and prevention and control is strengthened again. So, what are the risks in the limited space, often become the safety corner of the investigation control?

Limited space risk factors

The limited space is often closed or partly closed, the entrance and exit are narrow, the natural ventilation is bad, easy to cause toxic and harmful, flammable and explosive substances accumulation, so easy to cause poisoning asphyxiation, fire, explosion and other major accidents.

Point laser methane sensor

Point laser methane sensor is a kind of high-tech laser monitoring product, which integrates laser absorption spectrum gas detection technology, wireless transmission technology, low power consumption technology, computer technology and waterproof and explosion-proof technology. The product has safe and reliable performance and long service life, with strong corrosion resistance, high precision, fast response, low power consumption, can solve the gas accumulation in limited space security risks.

High sensitivity

CAN accurately detect trace gas leakage, fast response time, the emergence of small gas leakage alarm to do early detection and early disposal.

“Fingerprint” detection

High monitoring accuracy, can completely eliminate false positives, no need to re-check, make the safety management simple, once the alarm can be taken immediately.

No calibration is required

Without calibration, the problem of frequent adjustment of traditional monitoring equipment is solved, and the later maintenance workload and operation cost are greatly reduced.

Strong anti-interference ability

Free from humidity, dust, temperature and other gases, can work in a high humidity environment for a long time.

It has the function of fault self-diagnosis

Such as equipment, laser detectors, such as failure, the instrument automatically diagnosis and can be reported to the data center.

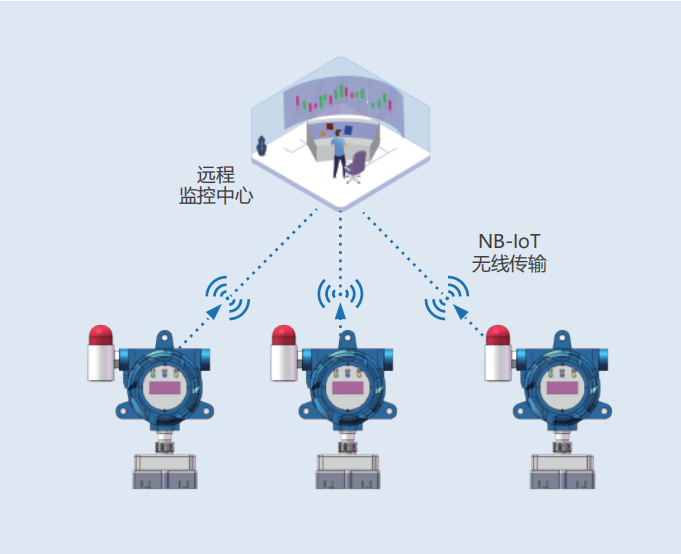

Internet of things technology is available

The area covered by the network can be used regardless of distance and range.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone