ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

Recently, the safety code for special operations in hazardous chemical enterprises was approved and issued, which stipulates the new technical requirements under special operation environments such as hot work, limited space operation, blind plate pumping and blocking operation, high-altitude operation, hoisting operation, temporary power operation, earth moving operation and circuit breaking operation, which also means that the red line of safety management for special operations has been raised again.

Special operation has always been a difficult and accident prone link in the safety management of hazardous chemical enterprises. Take the limited space operation as an example. Due to its narrow space, poor ventilation, toxic, harmful, flammable and explosive gases are easy to accumulate beyond the standard, and even lead to the risk of poisoning or explosion, it is necessary to carry out the work of risk hidden danger investigation and safe operation control throughout. On the one hand, the safety code for special operations in hazardous chemical enterprises shows that it is urgent to strengthen special operations, including limited space, on the other hand, it also points out the direction for the implementation of safety work.

Compared with the 2014 version of the safety code for special operations of chemical production units, the newly issued safety code for special operations of hazardous chemical enterprises has been adjusted to be mandatory in the full text, and the following contents have been modified and added in terms of operation in limited space:

New safety code for confined space operation

Monitoring time

The monitoring time is changed from regular monitoring for at least 2H to continuous monitoring, and the operation site shall be equipped with portable or mobile gas detection alarm to continuously monitor the concentration of oxygen, combustible gas, steam and toxic gas in the limited space, and determine that the minimum oxygen content has also been increased from 18% to 19.5%

Work stoppage in confined space

During the shutdown of operation in limited space, warning signs shall be added and measures to prevent personnel from entering by mistake shall be taken; When using portable and mobile combustible gas detector and alarm or other similar means for analysis, the gas detector and alarm shall be tested according to relevant regulations and can be used only after passing the test. In special circumstances, it is necessary to calibrate the concentration of marker gas.

In the face of the numerous demands to pay attention to the changes of gas environment and on-site abnormal conditions at all times, the closed-loop treatment of potential safety hazards shall be deployed for the operation in limited space, so as to "light the light" for the operation in limited space, eliminate potential safety hazards and avoid accidents.

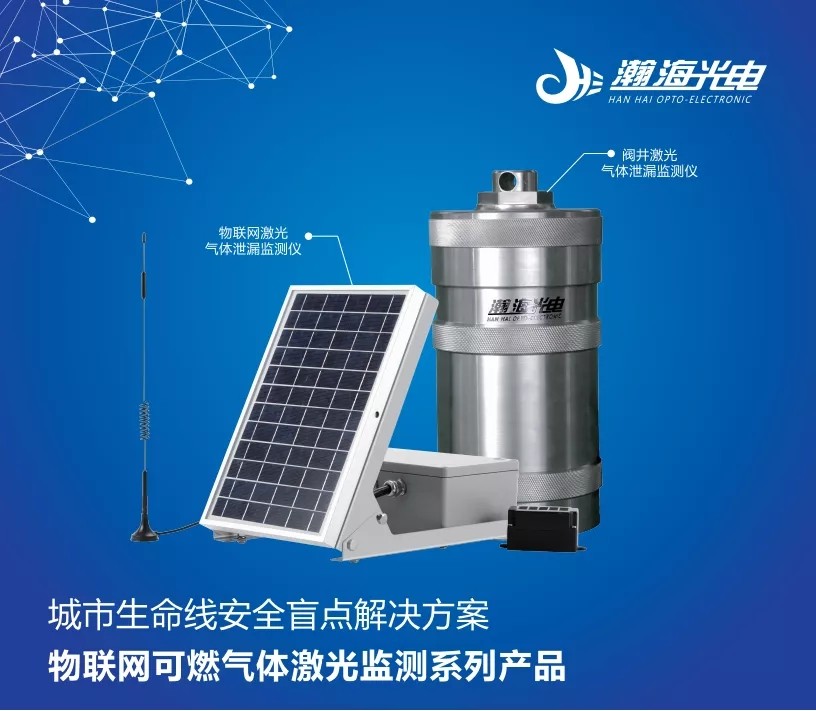

Laser gas leakage monitor

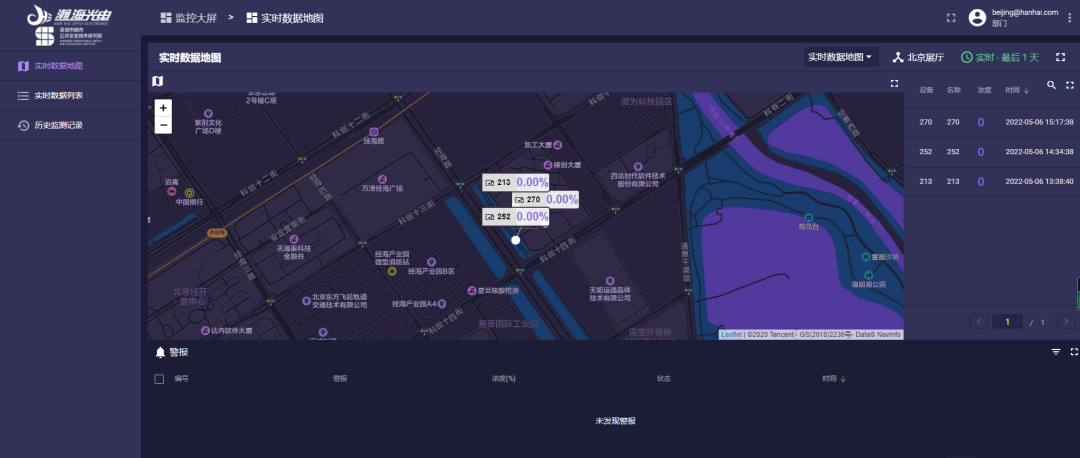

According to the characteristics of limited space, Hanhai photoelectric launched a laser gas leakage monitor. It is composed of detector, power supply and communication module and monitoring platform. It adopts laser absorption spectrum gas detection technology (TDLAS), low-power technology and Internet of things technology. The data is transmitted to the monitoring platform through NB lot Internet of things communication to realize real-time, fast, long-distance and accurate monitoring of trace gas leakage in underground, closed and semi closed spaces.

01 low power consumption

The laser gas leakage monitor of the Internet of things adopts solar energy and battery power supply, and uses intelligent monitoring system, ultra-low power consumption and ultra-long operation time to promote the effective monitoring of the end link.

02 preventive monitoring

The response time is less than 10 seconds, which can accurately detect ppm trace gas leakage, upload the monitoring and alarm data to the cloud platform, make the gas concentration data display more intuitive, help the full coverage monitoring of urban gas leakage, and truly realize the preventive monitoring of gas leakage.

03 easy installation

The modular design from detector to control system is adopted. The simplified system structure makes the installation easier.

04 strong anti-interference ability

It will not be disturbed by humidity, dust, temperature and other gases, and can work in high humidity environment for a long time.

05 omnidirectional NB lot Internet of things access

Using Internet of things technology, all areas covered by the network can be used without limitation of distance and scope.

06 waterproof alarm function

The water level monitoring function can monitor the accidental water inflow in the valve well in real time.

In addition, the convenient telemetry laser methane detector can also be used to detect the gas in the limited space before operation to avoid work accidents.

Convenient telemetry laser methane detector

Portable telemetry laser methane detector is based on laser absorption spectrum gas detection technology (TDLAS), non-contact measurement, which can realize long-distance and rapid detection in areas that are difficult for personnel to reach, accurately determine the leakage direction and quickly find the leakage source. The equipment can make the operators do not need to be in the dangerous gas environment, greatly improve the safety of the detection personnel and reduce the labor intensity at the same time.

01、Remote active telemetry

The monitoring mode of remote active telemetry does not need to contact the detection gas, and the detection distance can reach 150m.

02、High sensitivity

Portable design enables easy remote scanning of leakage risk points. The response time is only 0.1 second, which can accurately detect ppm micro leakage.

03、Strong anti-interference ability

Compared with the traditional detector, which is easy to be disturbed by environment and cross gas, it has strong anti-interference ability. Fingerprint detection, truly achieve zero false positives.

04、Simple operation

Color LED and all Chinese operation interface are closer to users.

05、Long endurance

With intelligent battery management technology, the product can last up to 16 hours.

06、Long life

The product has good stability, no need for regular adjustment and maintenance, and the service life is more than 10 years.

With the refresh of safety standards for special operations such as limited space operations, safety production equipment and systems have become the "Guardian" of enterprise development and provide intelligent solutions for enterprise safety management.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone