ABOUT

Hanhai Opto-electronic is a major scientific research achievement transformation institution of the Hefei Institute of Physical Science, Chinese Academy of Sciences.

On October 23-24, at the invitation of the urban underground comprehensive pipe gallery Working Committee of China Engineering Construction Standardization Association, Hanhai optoelectronics participated in the fourth national urban underground comprehensive pipe gallery Technology Innovation Summit Forum and the annual meeting of the urban comprehensive pipe gallery Working Committee of China Engineering Construction Standardization Association in 2021 held in xiong'an New Area.

The theme of this meeting is "green construction and smart management". The construction of xiong'an new area is a national event and a millennium plan. According to the planning outline of xiong'an new area, the new area will build an integrated pipe gallery system with a total length of trunk lines, branch lines and cables of more than 300 km. In the project construction, a series of new construction technologies have been developed and applied. The conference focused on green construction and intelligent management, and invited relevant principals of Hanhai optoelectronics to participate in academic exchanges. The meeting also invited Hanhai optoelectronics and its delegation, experts and scholars to visit the front line of the comprehensive pipe gallery project in xiong'an new area.

Li Shuguang, chairman of Hanhai optoelectronics, said: "The construction of urban comprehensive pipe gallery is a long-term plan. According to the requirements of the Ministry of construction, the urban comprehensive pipe gallery must include gas pipeline and sewage pipeline, and the gas pipeline and sewage pipeline enter the special gas bunker and sewage bunker respectively. Because the gas has the property of combustion and explosion, and the gas bunker belongs to a closed space, once the gas leakage occurs, it is not easy to spread, and it is easy to form aggregation, resulting in explosion accidents The sewage pipeline will also produce biogas and hydrogen sulfide gas, which will also cause explosion and poisoning accidents in the confined space of the sewage pipe gallery. Once the explosion accident of the comprehensive pipe gallery occurs, it will not only cause damage to facilities, collapse of the pipe gallery, casualties on the ground and damage to buildings. At the same time, due to the concentration of water, electricity and communication lines in the pipe gallery, it will also lead to large-scale water and power outage in the city If communication is interrupted, the consequences will be disastrous. Therefore, the gas safety of underground comprehensive pipe gallery has become an issue that must be carefully studied and treated in the construction of comprehensive pipe gallery. Safety should focus on prevention. The most important prevention means of dangerous gas disasters in urban comprehensive pipe gallery is the monitoring of these gases. This requires high safety and reliability, which can be used in real time for a long time The equipment for line monitoring also needs high standard construction specifications and strict operation and maintenance requirements. The traditional catalytic combustion and electrochemical sensors have problems such as false alarm, drift, failure, high concentration impact, poisoning and short service life. They can not carry out long-term reliable and effective monitoring and can not meet the safety requirements of underground pipe gallery. "

Hanhai optoelectronics has provided an effective gas monitoring solution for underground pipe gallery. Laser absorption spectrum detection technology is recognized as the most ideal detection technology in the scientific and technological circles. It overcomes all the defects of current catalytic combustion and electrochemical technology. It has fast reaction speed, high monitoring sensitivity, strong anti-interference, no false alarm, no adjustment and maintenance, and its service life is catalytic combustion and electrochemical technology Ten times that of electrochemistry, it can realize the real intrinsic safety of passive monitoring. In 2010, CAS and Shenzhen Hanhai technology company established the industrialization company of this technology. After ten years of dedicated research and development, it has developed a series of application products of laser absorption spectroscopy technology. The coal mine gas laser passive monitoring system developed by the company has been listed in the key promotion of the State Administration of work safety and the Ministry of science and technology Based on the laser passive monitoring system of coal mine gas, the newly developed system specially used for safety detection of comprehensive pipe gallery has also obtained the certification of the Fire Department of the Ministry of public security.

There is no doubt that Hanhai photoelectric passive optical fiber laser monitoring system using laser absorption spectrum gas detection technology is the most suitable monitoring product in underground pipe gallery.

Gas and biogas monitoring

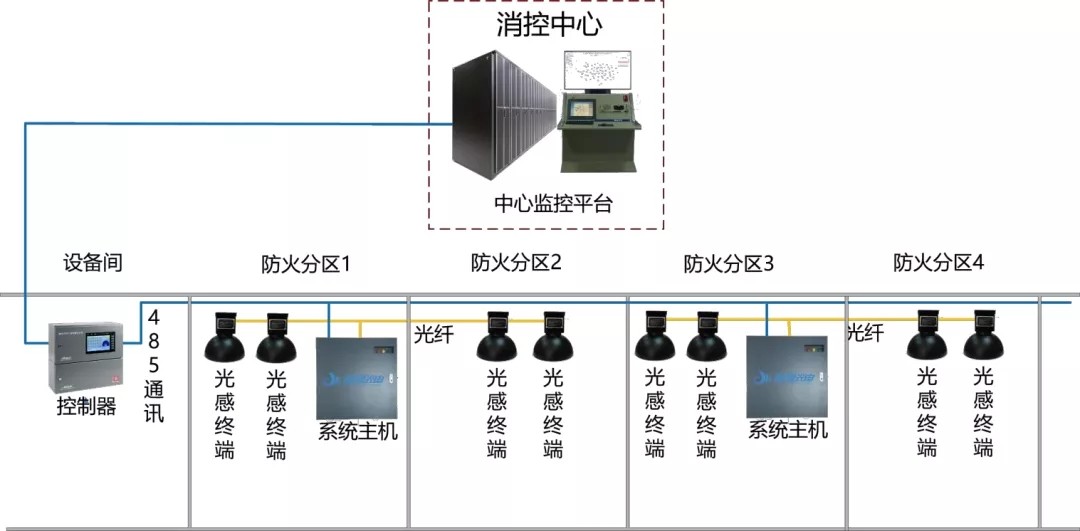

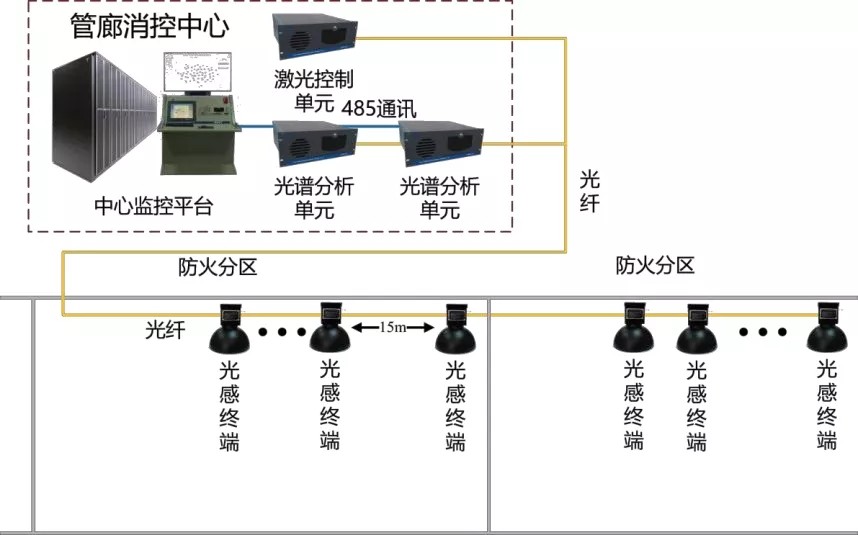

Passive fiber laser monitoring system is a passive on-line monitoring system. The system is composed of system host and passive light sensing terminal, which are connected through optical fiber. Just lay an optical cable along the pipe gallery and hang a light sensing terminal with the size of a lampshade every 15m to realize real-time monitoring of the whole pipe gallery.

Working diagram

Distributed

The laser emission, control unit and spectral analysis and processing unit are installed separately. The spectral analysis and processing unit can be superimposed. It can support 256 light sensing terminals at most and monitor multiple fire compartments.

The light sensing terminal shall be installed 0.5-2m above the pipeline (according to the site height), one at an interval of 15m, and installed by roof hoisting or wall fixed support. Two core optical cables are used to connect with the system host without power supply. The laser control unit is placed in the fire control center, and the spectral analysis unit can be installed at the monitoring site or at the same place as the host. One laser control unit can support 16 spectral analysis units; Each spectral analysis unit can support 16 light sensing terminals. The laser control unit and spectrum analysis unit are powered by 24VDC. The spectral analysis unit outputs the monitoring results through RS485.

TEL:400-055-1239 (9:00~17:00)

MAIL:lisghanhai@gkhhlaser.com

ADDR:302 Floor, Building 5, No. 18, Kechuang 13th Street, Beijing Economic and Technological Development Zone